ABOUT EOTRON

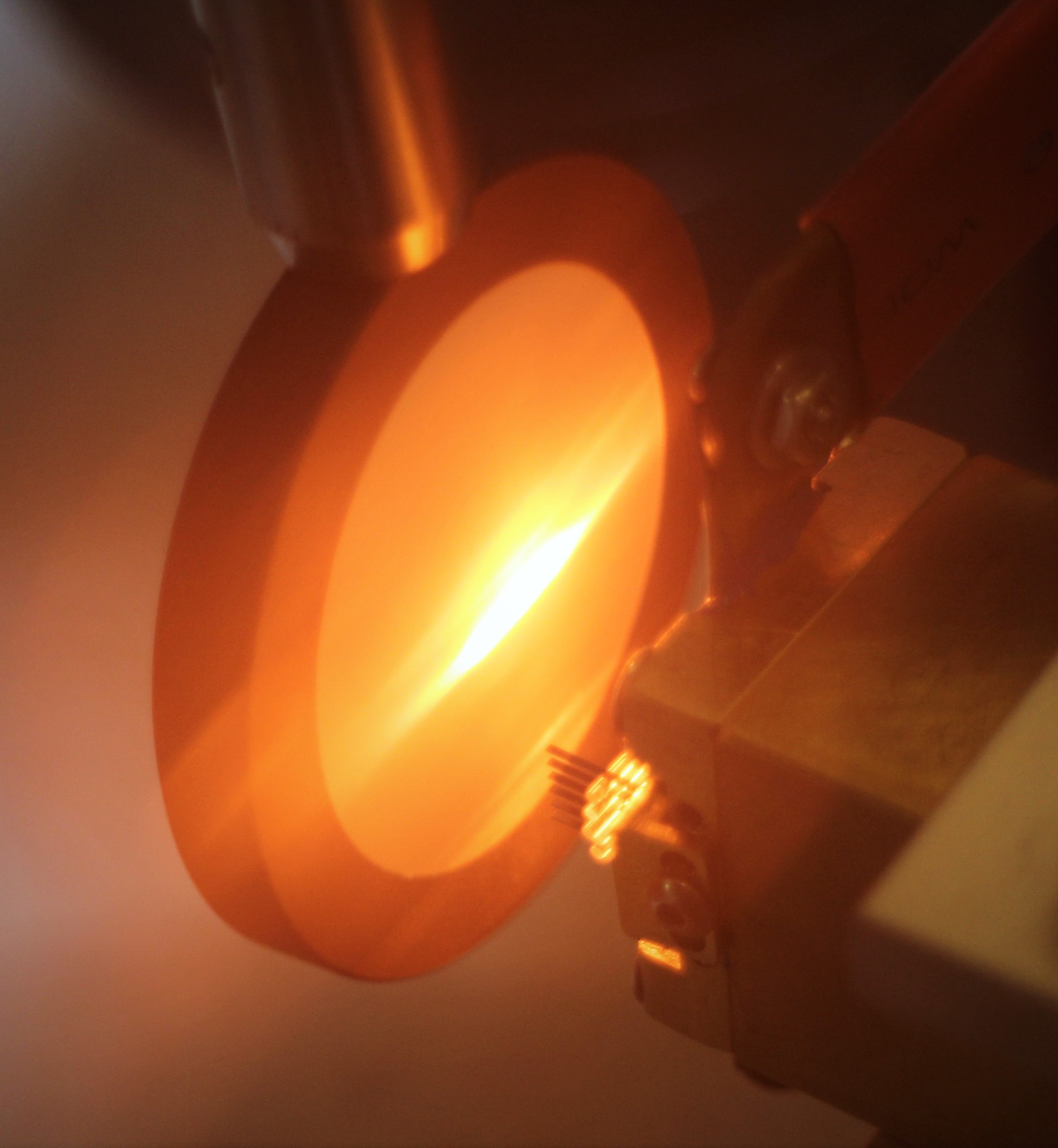

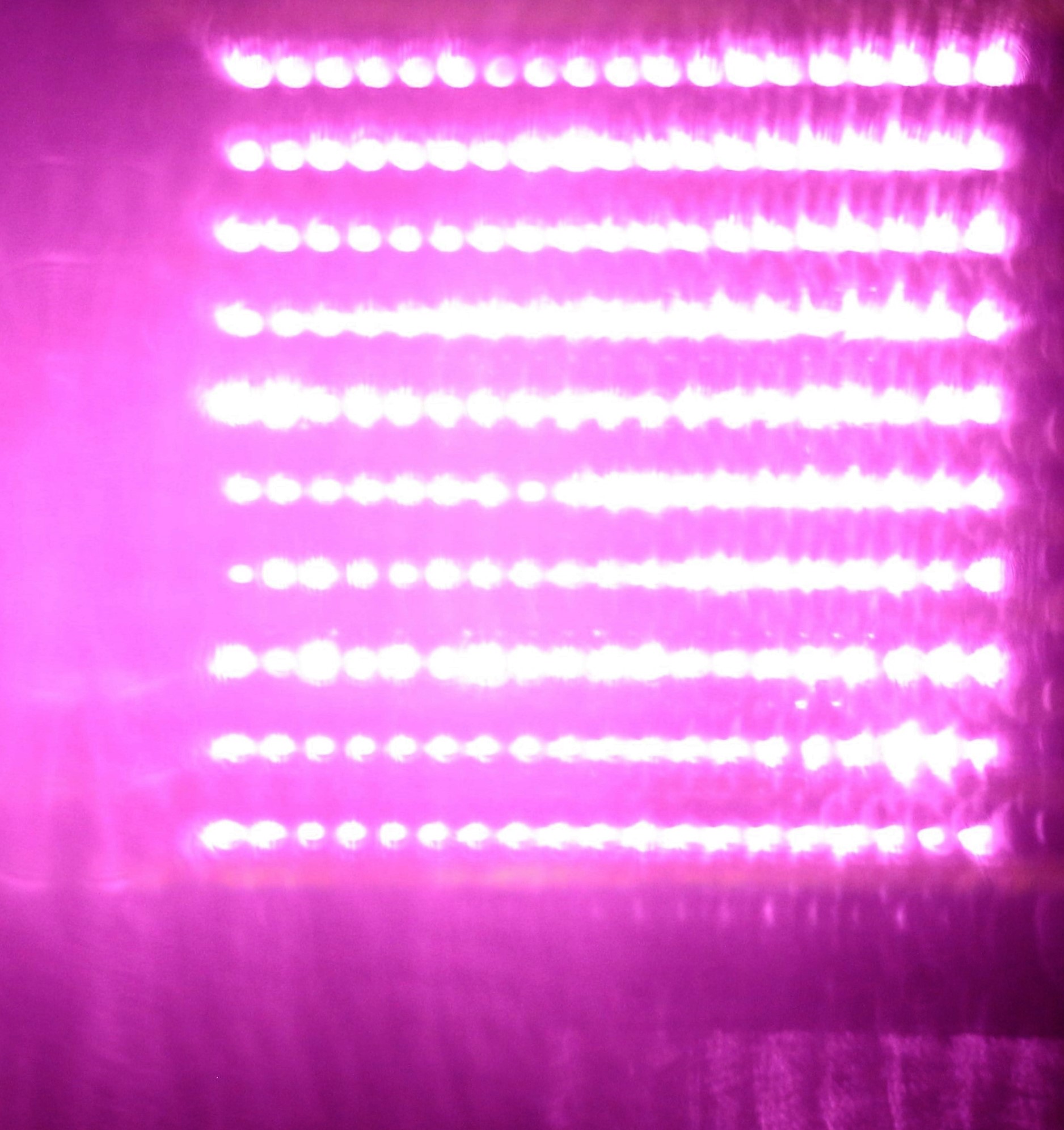

Eotron LLC was founded in 2006 primarily to develop a compact DPSS

laser using a silicon substrate to contain all pump diodes and optical

mounts on one silicon based MEMS bench. The main challenge in building

this silicon-bench was dissipating the large amount of waste heat from

the pump diodes and solid-state crystal. It was also very challenging

to integrate all the optical components using a 2D configuration while

removing all of the waste heat. Therefore, a configuration using a 3D

Silicon structure containing a high power diode stack was conceived,

designed, fabricated and tested in 2011.

Eotron LLC was founded in 2006 primarily to develop a compact DPSS

laser using a silicon substrate to contain all pump diodes and optical

mounts on one silicon based MEMS bench. The main challenge in building

this silicon-bench was dissipating the large amount of waste heat from

the pump diodes and solid-state crystal. It was also very challenging

to integrate all the optical components using a 2D configuration while

removing all of the waste heat. Therefore, a configuration using a 3D

Silicon structure containing a high power diode stack was conceived,

designed, fabricated and tested in 2011.

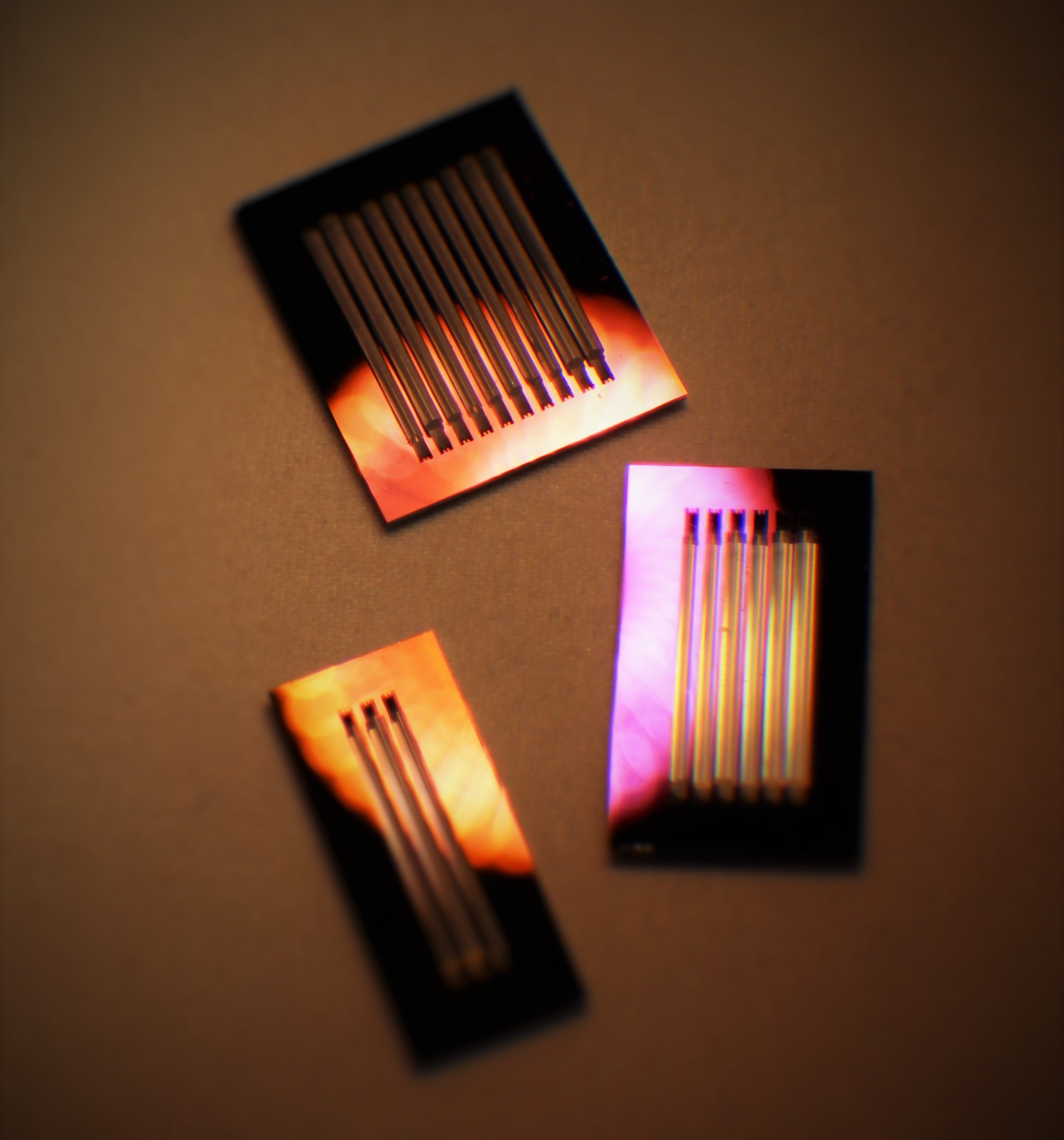

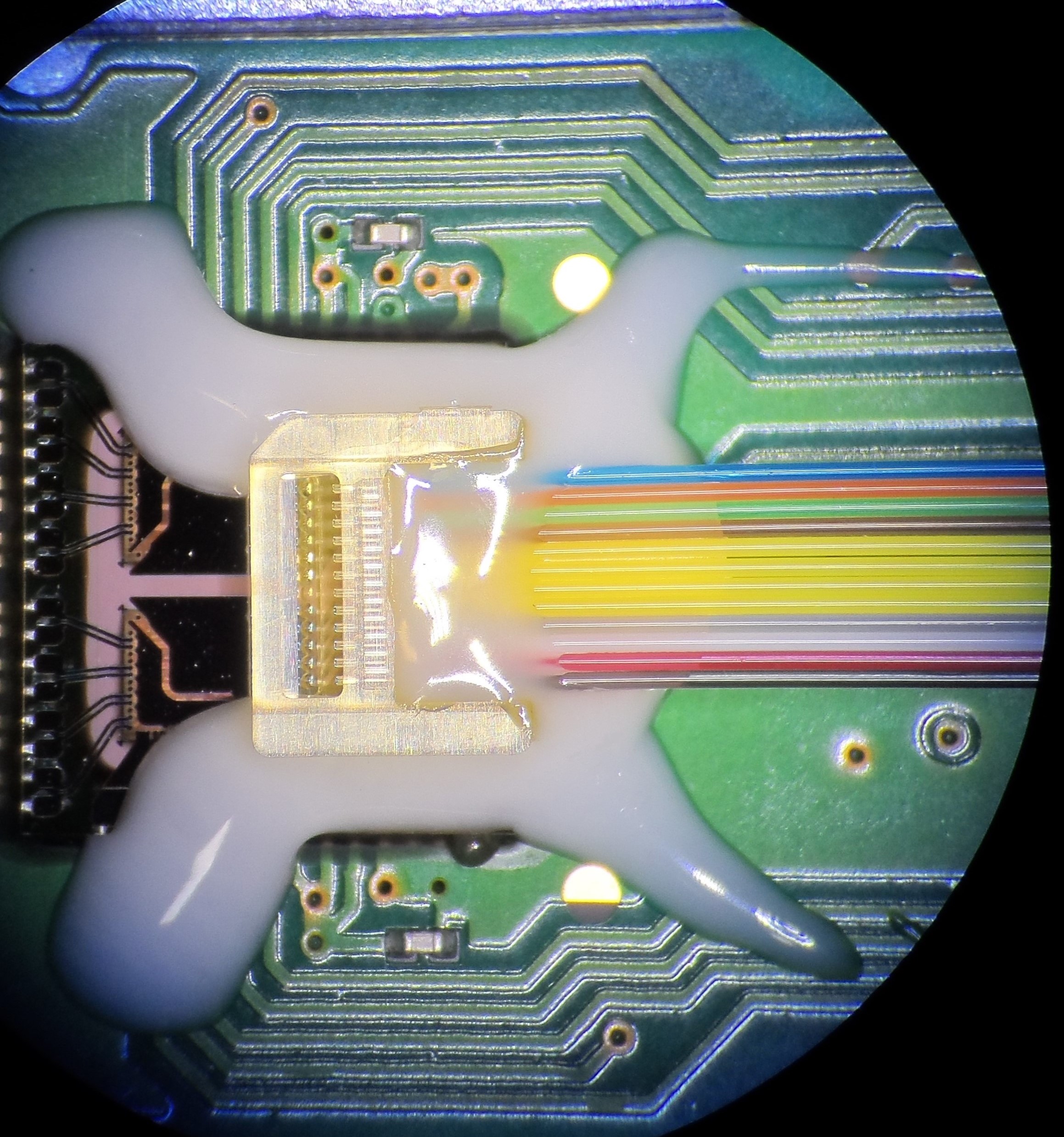

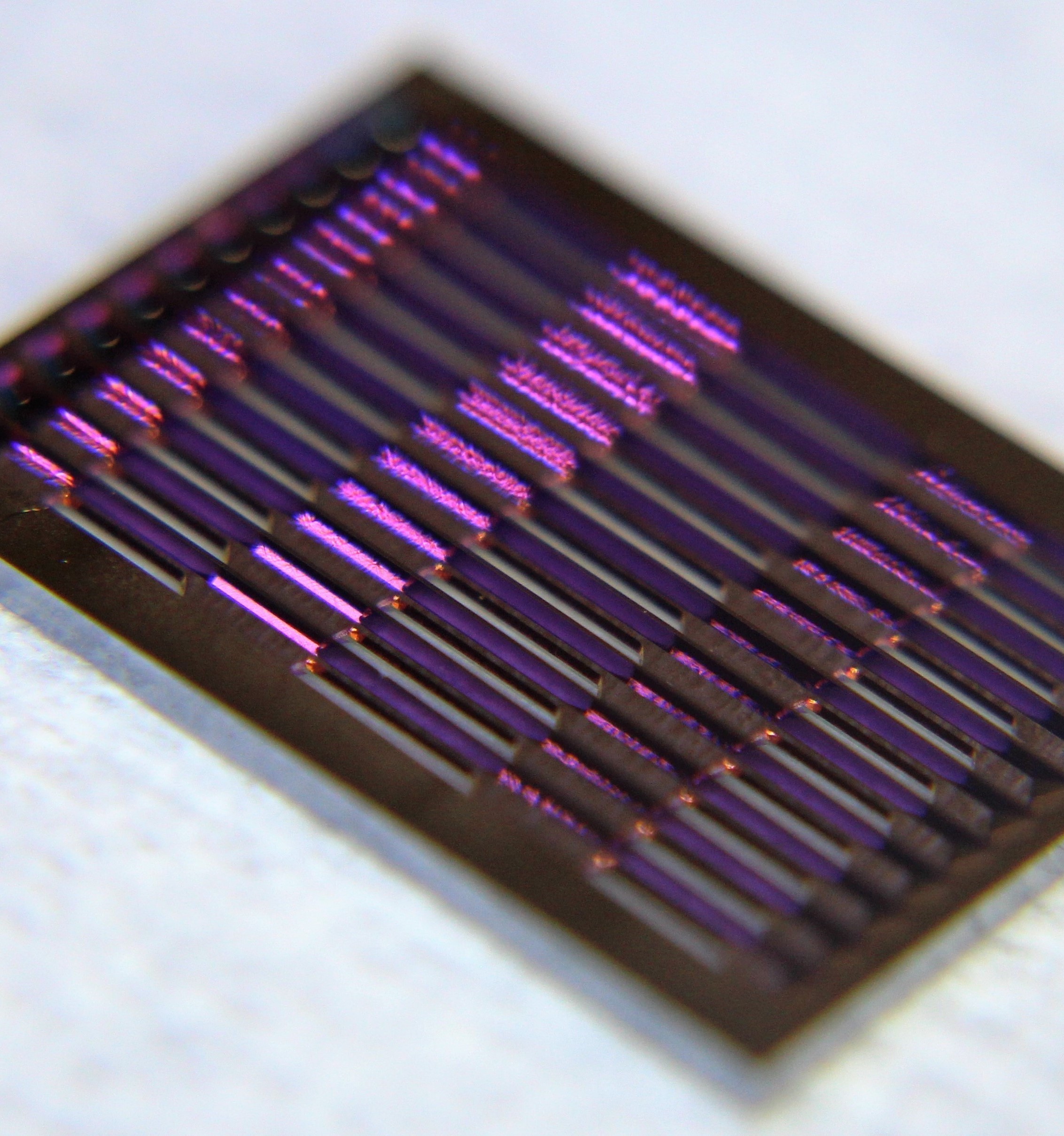

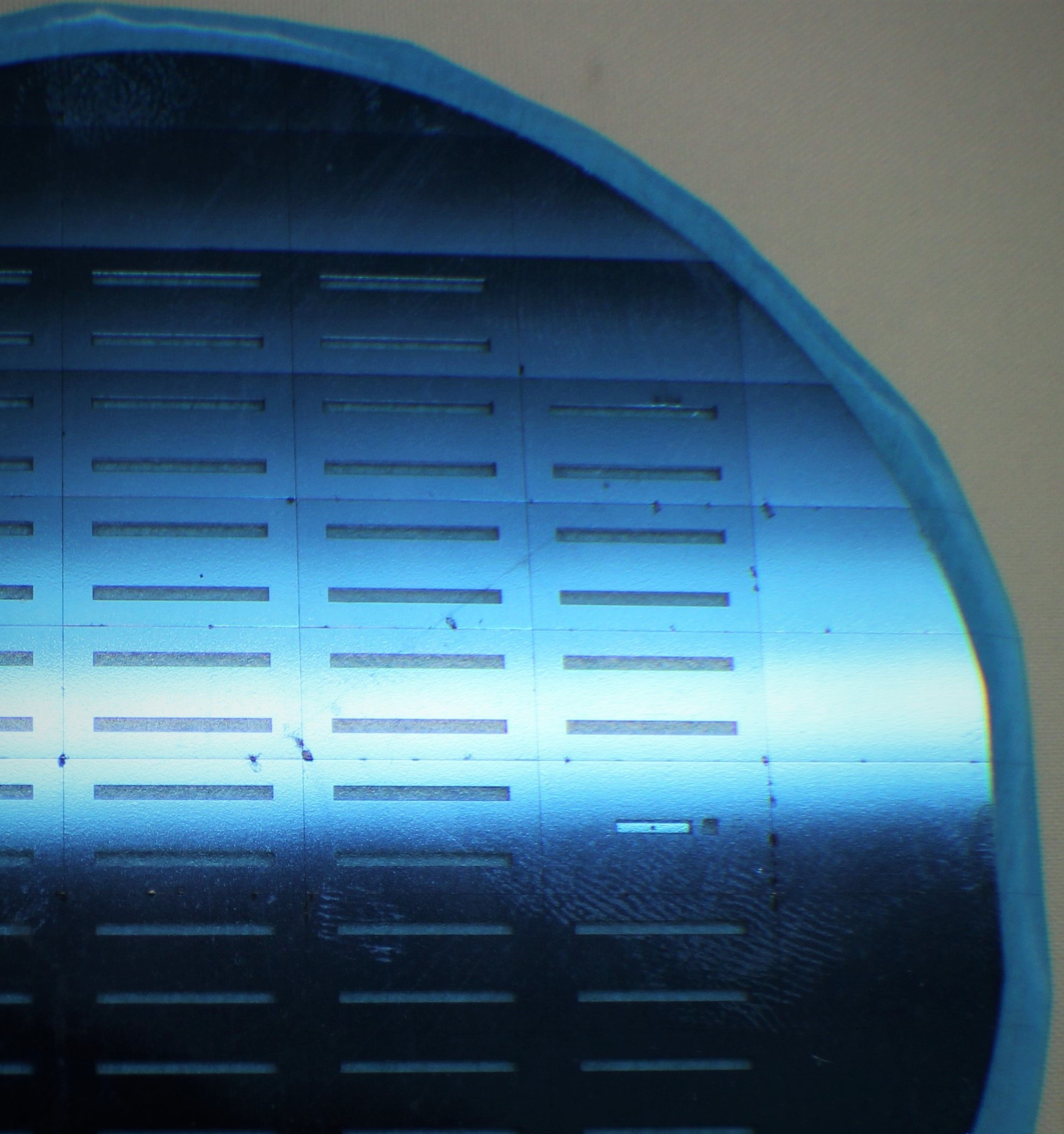

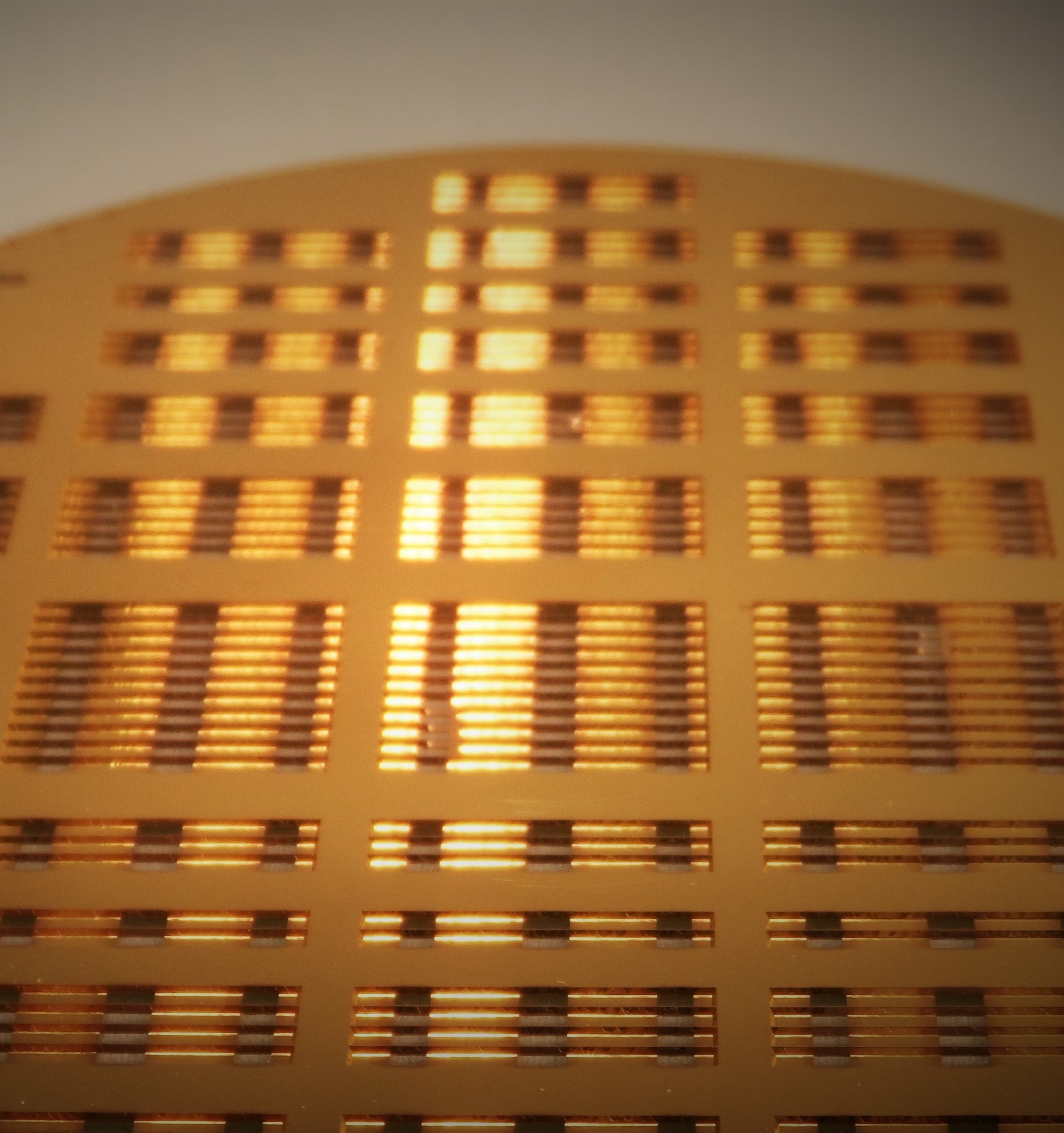

The resulting high power silicon diode laser stack was further

developed in 2012 using an improved 3D silicon structure and a number

of proprietary Silicon MEMS fabrication processes. All techniques and

patents were developed under private funding. Based on these

accomplishments, Eotron was awarded with several SBIR Phase 1 and

Phase 2 contracts from the Air Force, Missile Defense Agency, Navy and

NASA to develop new concepts in cooling high power lasers and other

electronic devices and systems.

Building on the technology and continued research, Eotron expanded its

offering to include 3D Silicon components, designs and techniques

aimed at improving thermal management of both electronic and photonic

devices with high thermal flux. These designs, components and

expertise have led to interest and development projects from the

commercial marketplace, including from leading Fortune 100 companies.

Eotron currently has over 20 awarded patents related to active and

passive cooling using 2D and 3D silicon structures, with another 20 or

more pending.

Eotron is located in Oceanside, CA, where it maintains a 4500 sq. ft

facility with engineering labs and class 10,000 clean room. The

company leases access to a silicon wafer fabrication MEMS facilities

in US, staffed by Eotron employees, with volume production handled by

dedicated silicon foundry suppliers with world-wide locations.

Eotron LLC was founded in 2006 primarily to develop a compact DPSS

laser using a silicon substrate to contain all pump diodes and optical

mounts on one silicon based MEMS bench. The main challenge in building

this silicon-bench was dissipating the large amount of waste heat from

the pump diodes and solid-state crystal. It was also very challenging

to integrate all the optical components using a 2D configuration while

removing all of the waste heat. Therefore, a configuration using a 3D

Silicon structure containing a high power diode stack was conceived,

designed, fabricated and tested in 2011.

Eotron LLC was founded in 2006 primarily to develop a compact DPSS

laser using a silicon substrate to contain all pump diodes and optical

mounts on one silicon based MEMS bench. The main challenge in building

this silicon-bench was dissipating the large amount of waste heat from

the pump diodes and solid-state crystal. It was also very challenging

to integrate all the optical components using a 2D configuration while

removing all of the waste heat. Therefore, a configuration using a 3D

Silicon structure containing a high power diode stack was conceived,

designed, fabricated and tested in 2011.